Double Offset Butterfly Valve Series 2000 Catalogue

Features and Benefits

The TIPBV Double Offset Butterfly Valve is a rugged and dependable resilient seated, double offset valve designed for high performance in water treatment facilities, pipelines, pump stations, and industrial settings. This high specification valve is built to last with a weld overlaid body seat, innovative dry shaft, and fusion bonded epoxy coating.

Fully conforms to AWWA Standard C504:

All TIPBV Double Eccentric Butterfly Valves comply with AWWA C504 and are designed for a long servi ce life with little attention or need for maintenance. S tainless steel shafts are corrosion resistant. Chevro n V-Type packings are used to last the life ofthe val ve without adjustment.

Low torque:

The thrust bearing assembly and leveler screw (pro vided on valves of 24" and larger) assures balance and centers the disc for minimum disc seat wear wit hout galling, providing constant low torque requirem ents.

Field replaceable rubber seat:

Specially compounded Buna N seat seals a full 360 degree against a stainless steel spherical disc edge. Unique grooved-seat design, coupled with the wide, spher ically shaped seating edge of the disc, allows greate r disc closure tolerance (up to1 degree off center in closed position without leakage). Seat is mechanically reta ined in body without metal hardware by a cast epox y compound that ensures the seat conforms to the p recise radius of the disc with uniform contact pressu re. It is fully field adjustable and replaceable.

Ease of Maintenance:

The Double Offset design requires zero to minimal maintenance. The bearing cover allows the user to r emove the worm gear without dewatering the pipelin e. In the event of seal replacement or repair it can b e accomplished in the field, with common tools, with out the need of epoxy injections or a specialized tec hnician.

Structure and Benefits

Design Standard

Valve Design:

EN593/AWWA C504

Face to Face:

EN558-1 / ANSI B16.10

End Flange Connection:

EN1092/ANSI B16.47/ANSI B16.5

Upper Flange Connection:

ISO 5211

Type | Soft Seal Eccentric Butterfly Valve | AWWAC504 Butterfly Valve | |||

Nominal Diameter (DN/Inch) | 600-3000 | 100-2600 | 100-1200 | 3"-72" | |

Nominal Pressure (PN/PSI) | 0.6 | 1 0 | 1.6 | 150PSI | |

Test Pressure | Sealing | 0.66 | 11 | 1.76 | 165PSI |

Shell | 0.9 | 1 5 | 2.4 | 225PSI | |

Working Temperature ( degree ) | -10-80 | -10-80 | |||

Suitable Media | Fresh water, Sewage, Sea water etc. | ||||

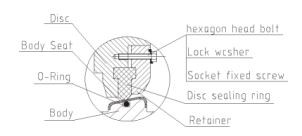

Sealing Structure and Features

Technical Specification

•"n" type stainless steel ring inlaid in valve body, can rust proof permanently, and also prevent the vibration caused by unstable water flow speed and the valve failure caused by fastener loosen and fallen down, improve adaptability of bad condition

•"n" type stainless steel ring underside adopt ring belt, O type sealing saved material and simple process, greatly reduce product cost

•"T" type disc rubber as main seal ring ,reaches bi-direction seal, prevent from force falling in on-off operation

•Available with lock washer and set screw, ensure disc pressure ring in right position

Main Parts Materials

No, | Name | Material |

Bushing | ZCuZn38Mn2Pb2, F4 backing Steel | |

2 | Bottom sha | 304 416 420 431 |

3 | Disc | QT450-10 A536 65-45-12 |

4 | Taper pin | 304 416 420 431 |

5 | Top sha代 | 304 416 420 431 |

6 | Body | HT200 A126ClassB QT450-10 A536 65-45-12 |

7 | Packing | NBR EPDM |

8 | Retainer | QT450-10 A536 65-45-12 Q235-A Gr33 |

9 | Disc sealing ring | NBR EPDM |

10 | Body steel ring | 316 |

11 | Sealing ring | NBR EPDM |

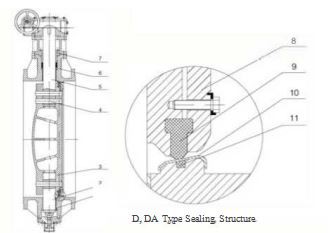

A: Body Made of high strength materials, little deforma tion, adapt t.bad working conditions. B: Body Sealing Ring Stainless steel sealing ring, integral rolling on body, high precision, wear-resistant, long service life. C: Disc Sealing Ring: T type sealing rubber ring, integrate moulded form, high precision, reach bi-direction seal. D, DA Type Sealing Structure E: Taper pin High precision, connect shaft with disc effi ciently F: Pin-Sealing Ring Fix the taper pin reliably, prevent falling, G: Packing Gland Reach upper shaft fixed position, and fix the seal ring. H: O-Ring Multiplex.-Rings can prevent stem end leakage. | I: Bushing Made of lubricant and small friction coefficient material, support shaft and reduce rotation torque. J: Shaft High strength stainless steel shaft can deliver torque effectively. K: Wearing Washer Prevent the splint ring and shaft shoulder from wearing, reduce rotation torque, and assure the shaft in right position. L: O-Ring Prevent end from leakage efficiently. M: Bottom Cover Through supporting splint ring, prevent disc from falling, and assure the sealing perfor mance. N: Splint Ring Assure the shaft in right position. |

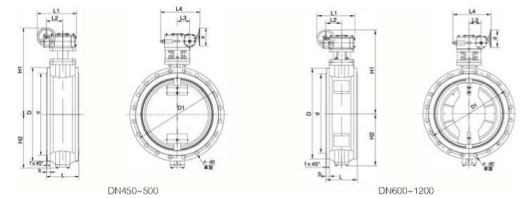

Overall Dimensions and Weights

PN10(Unit:mm,Kg)

DN | Gear Operator | L | D | D1 | d | n | d0 | b | f | H1 | H2 | L1 | L2 | L3 | L4 | 0 | Weight |

100 | XJ24 | 127 | 220 | 180 | 156 | 8 | 19 | 19 | 3 | 310 | 109 | 52 | 45 | 158 | 210 | 150 | 19 |

150 | XJ24 | 140 | 285 | 240 | 211 | 8 | 23 | 19 | 3 | 440 | 143 | 52 | 45 | 158 | 210 | 150 | 37 |

200 | XJ30 | 152 | 340 | 295 | 266 | 8 | 23 | 20 | 3 | 510 | 182 | 77 | 63 | 238 | 315 | 300 | 51 |

250 | XJ30 | 165 | 395 | 350 | 319 | 12 | 23 | 22 | 3 | 565 | 219 | 77 | 63 | 238 | 315 | 300 | 68 |

300 | 4022 | 178 | 445 | 400 | 370 | 12 | 23 | 24.5 | 4 | 630 | 244 | 95 | 72 | 167 | 242 | 300 | 93 |

350 | 4023 | 190 | 505 | 460 | 429 | 16 | 23 | 24.5 | 4 | 715 | 283 | 110 | 91 | 188 | 275 | 400 | 122 |

400 | 4023 | 216 | 565 | 515 | 480 | 16 | 28 | 24.5 | 4 | 750 | 312 | 110 | 91 | 188 | 275 | 400 | 152 |

PN10(Unit:mm,Kg)

DN | Gear Operator | L | D | D1 | d | n | d0 | b | f | H1 | H2 | L1 | L2 | L3 | L4 | 0 | Weight |

450 | 4024 | 222 | 615 | 565 | 530 | 20 | 28 | 25.5 | 4 | 820 | 344 | 473 | 147 | 109 | 420 | 400 | 182 |

500 | 4024 | 229 | 670 | 620 | 582 | 20 | 28 | 26.5 | 4 | 845 | 381 | 473 | 147 | 109 | 420 | 400 | 230 |

600 | 4025 | 267 | 780 | 725 | 682 | 20 | 31 | 30 | 5 | 950 | 451 | 533 | 179 | 138 | 476 | 400 | 388 |

700 | 4025 | 292 | 895 | 840 | 794 | 24 | 31 | 32.5 | 5 | 1010 | 526 | 533 | 179 | 138 | 476 | 400 | 480 |

800 | 4026 | 318 | 1015 | 950 | 901 | 24 | 34 | 35 | 5 | 1140 | 581 | 655 | 217 | 170 | 577 | 500 | 661 |

900 | 4026 | 330 | 1115 | 1050 | 1001 | 28 | 34 | 37.5 | 5 | 1197 | 643 | 655 | 217 | 170 | 577 | 500 | 813 |

1000 | 4026 | 410 | 1230 | 1160 | 1112 | 28 | 37 | 40 | 5 | 1277 | 722 | 655 | 217 | 170 | 577 | 500 | 1018 |

1200 | 4027 | 470 | 1455 | 1380 | 1328 | 32 | 40 | 45 | 5 | 1511 | 840 | 748 | 262 | 202 | 664 | 500 | 1501 |

Overall Dimensions and Weights

PN6/PN10(Unit:mm,Kg)

Pressure | DN | Gear Operator | D | D1 | d | b | f | n-d0 | L | H1 | H2 | L1 | L2 | L3 | L4 | L5 | 0 | A | 4-S | B | E | F | h | Weight |

PN10 | 1400 | 4028 | 1675 | 1590 | 1530 | 46 | 5 | 36-43 | 530 | 1750 | 1150 | 884 | 334 | 305 | 238 | 790 | 500 | 310 | 33 | 1500 | 1360 | 1590 | 960 | 2895 |

1600 | 4028 | 1915 | 1820 | 1750 | 49 | 5 | 40-49 | 600 | 1870 | 1305 | 884 | 334 | 305 | 238 | 790 | 500 | 340 | 33 | 1600 | 1460 | 1700 | 1050 | 3655 | |

1800 | 4028.5 | 2115 | 2020 | 1950 | 52 | 5 | 44-49 | 670 | 2125 | 1425 | 977 | 357.5 | 323 | 281 | 855 | 600 | 450 | 36 | 1900 | 1740 | 1990 | 1200 | 5210 | |

2000 | 4029 | 2325 | 2230 | 2150 | 55 | 5 | 48-49 | 760 | 2280 | 1580 | 1059 | 397.5 | 345 | 307.5 | 903 | 600 | 480 | 36 | 2000 | 1850 | 2100 | 1323 | 6721 | |

2200 | 4029.5 | 2550 | 2440 | 2370 | 58 | 6 | 52- 56 | 580 | 2520 | 1710 | 1222 | 436 | 437.5 | 365.5 | 1075 | 800 | 400 | 36 | 2030 | 1830 | 2150 | 1410 | 7658 | |

2400 | 40210 | 2760 | 2650 | 2570 | 62 | 6 | 56-56 | 750 | 2760 | 1880 | 1303 | 476 | 480 | 410.5 | 1191 | 800 | 490 | 45 | 2310 | 2120 | 2460 | 1470 | 10350 | |

2600 | 40211 | 2960 | 2850 | 2780 | 66 | 6 | 60-56 | 900 | 3120 | 2010 | 1744 | 605 | 612 | 521 | 2024 | 1000 | 650 | 45 | 2400 | 2210 | 2540 | 1650 | 13708 | |

PN6 | 1400 | 4027 | 1630 | 1560 | 1510 | 38 | 5 | 36-37 | 530 | 1695 | 1150 | 748 | 262 | 259 | 202 | 664 | 500 | 310 | 33 | 1500 | 1360 | 1590 | 960 | 2623 |

1600 | 4028 | 1830 | 1760 | 1710 | 40 | 5 | 40-37 | 600 | 1870 | 1305 | 884 | 334 | 305 | 238 | 790 | 500 | 340 | 33 | 1600 | 1460 | 1700 | 1050 | 3559 | |

1800 | 4028 | 2045 | 1970 | 1918 | 42 | 5 | 44-40 | 670 | 2015 | 1425 | 884 | 334 | 305 | 238 | 790 | 500 | 450 | 36 | I860 | 1700 | I960 | 1180 | 4615 | |

2000 | 4028.5 | 2265 | 2180 | 2125 | 45 | 5 | 48-43 | 760 | 2235 | 1580 | 977 | 357.5 | 323 | 281 | 855 | 600 | 480 | 36 | I960 | 1810 | 2060 | 1303 | 6162 | |

2200 | 4029 | 2475 | 2390 | 2335 | 48 | 6 | 52-43 | 580 | 2380 | 1710 | 1059 | 397.5 | 345 | 307.5 | 903 | 600 | 400 | 36 | 1970 | 1770 | 2090 | 1380 | 6735 | |

2400 | 4029.5 | 2685 | 2600 | 2545 | 52 | 6 | 56-43 | 750 | 2720 | 1880 | 1222 | 436 | 437.5 | 365.5 | 1075 | 800 | 490 | 45 | 2310 | 2120 | 2460 | 1470 | 9586 | |

2600 | 4029.5 | 2905 | 2810 | 2750 | 54 | 6 | 60-49 | 900 | 2870 | 2010 | 1222 | 436 | 437.5 | 365.5 | 1075 | 800 | 650 | 45 | 2400 | 2210 | 2540 | 1650 | 12387 | |

2800 | 40210 | 3115 | 3020 | 2960 | 56 | 6 | 64-49 | 1000 | 3035 | 2050 | 1303 | 476 | 480 | 4105 | 1191 | 800 | 860 | 45 | 2540 | 2300 | 2700 | 1760 | 14238 | |

3000 | 40211 | 3315 | 3220 | 3160 | 60 | 6 | 68-49 | 1000 | - | 2300 | 1744 | 605 | 612 | 521 | 2024 | 1000 | 860 | 45 | 2650 | 2520 | 2920 | 1840 | - |

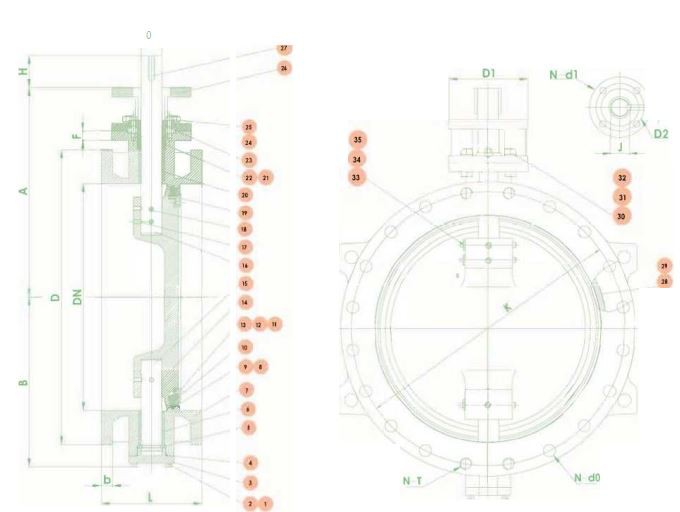

Main Parts Materials for AWWA C504 Butterfly Valve

NO. | NAME | QTY | MATERIAL | NOTE |

1 | Spring Gasket | 8 | 304 |

|

2 | Hexagon Bolt | 8 | 304 |

|

3 | Bottom Cover | 1 | ASTMA536 |

|

4 | Bottom Cover Seal | 1 | EPDM | NBR |

5 | Bisect Ring | 1 | 304 |

|

6 | LowerBushing | 1 | 316 plus TEFLON |

|

7 | Body | 1 | ASTMA536 |

|

8 | Body Seal | 1 | EPDM | NBR |

9 | Body Sealing Steel Ring | 1 | 316L |

|

10 | Disc Seal | 1 | EPDM | NBR |

11 | Hexagon Bolt | 40 | 304 |

|

12 | External Tab Gasket | 1 | 304 |

|

13 | Internal Hexagon Flat End Tightening Screw | 20 | 304 |

|

14 | Disc | 1 | ASTMA536 |

|

15 | Lower Shaft | 1 | SS304 |

|

16 | Upper Shaft | 1 | SS304 |

|

17 | Rper End Screw | 3 | SS304 |

|

18 | TaperPin | 3 | 304 |

2. | NAME | QTY | MATERIAL |

19 | Pressure Ring | 1 | 304 |

20 | Upper Bushing | 1 | 316 plus TEFLON |

21 | Packing Ring | 1 | 304 |

22 | O-ring | 4 | EPDM(NBR) |

23 | Packing Gland | 1 | ASTMA536 |

24 | Hexagon Nut | 2 | 304 |

25 | Double End Studs | 2 | 304 |

26 | Connection Support | 1 | ASTMA536 |

27 | General Flat Key | 2 | 45 |

28 | Label | 1 | H62 |

29 | Label Rivet | 4 | 304 |

30 | Hexagon Bolt | 8 | 304 |

31 | Hexagon Nut | 8 | 304 |

32 | Spring Gasket | 8 | 304 |

33 | Taper Pin Gasket | 3 | 304 |

34 | Hexagon Nut | 3 | 304 |

35 | Spring Gasket | 3 | 304 |

|

|

|

Popularni tagovi: double offset butterfly valve series 2000 catalogue, China, manufacturers, factory, customized, wholesale, price, cheap, in stock, for sale, free sample

Pošaljite upit